Technologies

Low activation concrete

Nuclear reactors and particle accelerators for medicine and research use, among other things, concrete shielding to block radiation, and when the reactor is scrapped or the equipment is dismantled, radioactive waste is produced. Using low activation concrete makes it possible to reduce the amount of radioactive waste produced.

This concrete is just as easy to work and process as normal concrete.

This concrete can reduce the enormous disposal costs resulting from the production of radioactive waste.

Environment simulation

Noise and vibration simulations

We can estimate how noise and vibration produced during construction and by building operations will affect the neighborhood.

We estimate noise and vibration and assess changes to the surrounding environment. We propose effective countermeasures

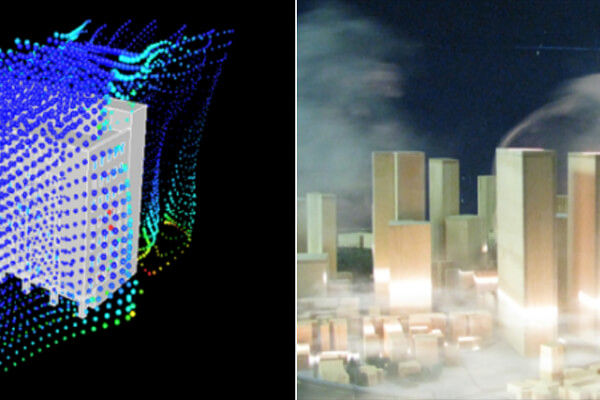

Wind environment simulations

We estimate changes to the wind environment surrounding the building.

We estimate wind direction and speed and assess changes to the surrounding environment. We propose effective countermeasures.

The stabilized muddy soil embankment method

If a fill dam embankment needs repairs, bottom mud and other accumulated soil can be freely used to produce embankment soil with excellent strength, water shielding properties, and deformation resistance.

This method is useful for both repairing embankments and removing bottom mud.

No money is spent purchasing embankment soil.

Even if the soil undergoes deformation, it sticks together and resists cracking.

The maintenance-free festa method

This method prevents algal growth and improves water quality without the need for ongoing maintenance, with the installation of floating islands for growing rabbit-ear irises and other aquatic plants in ponds.

The plants on the floating island grow back each year without the need for gardening maintenance.

Water quality can be improved without the need for any manual intervention.

Floating islands become a habitat for aquatic organisms, helping to preserve biodiversity.

The star-shaped foundation beam construction method

This construction method provides efficient reinforcement and lets us reduce the height of foundation beams compared with conventional methods. This is done by combining two isosceles triangle-shaped rebars into a star shape.

This method is ideal for condominiums, service-oriented residences for the elderly, hospitals, schools, and steel-frame buildings with pits.

It shortens construction time and reduces construction costs.

The F-ED method for high-quality pile construction

Fujita is able to construct high-quality, high-performance earth-drilled piles using five technologies that incorporate proprietary improvements.

We construct high-quality piles with greater construction accuracy than conventional methods.

We have achieved reliable earthquake-proof performance by making changes to pile head concrete compaction and reinforced frame assembly.

Yureiza III, a floor vibration analysis system

By using Yureiza III, a floor vibration analysis system, we can predict floor vibrations with high precision over short periods of time and take that into account in our designs.

Ideal for designing spaces that span large areas with few columns and are prone to swaying.

Floor vibration can be shown via 3D animation.

We have developed and put into practice a variety of technologies for counteracting vibration, including a device (a tuned mass damper, or TMD) that absorbs vibration by means of a moving weight.

FCF

This system uses multiple robotic jacks to raise work platforms that include integrated scaffolding and forms. Because it can be assembled and disassembled on the ground, it is very safe and economical.

Control devices and sensors allow the work platform to remain level while being raised.

This technique combines the advantages of the form construction method and the sliding form method.

The FCF method combined with aluminum dome roofing allows the installation of safer work platforms with fewer constraints for constructing dome roofs.

Hybrid building systems (the FSRPC-B and FRASH construction methods)

The FSRPC-B construction method is a proprietary Fujita technology that uses column and beam joints that combine reinforced concrete columns with steel beams. The FRASH construction method is a new hybrid method that uses reinforced concrete wrapped around the ends of steel beams.

We create column-less wide open spaces for logistics facilities, commercial facilities, hospitals, offices, and more.

Our construction times and costs are lower than when conventional steel-reinforced concrete columns and steel beams are used.

By combining conventional reinforced concrete and steel construction methods, we enable more flexible materials election and achieve more streamlined construction systems.

Strengthening buildings against earthquake

Fujita offers a number of seismic isolation technologies

Seismic isolation technology

Installing seismic isolators between the building and the ground inhibits the transfer of earthquake ground movements to the building.

Seismic quake control technology

The use of seismic quake control devices installed inside buildings greatly inhibits the swaying of buildings during earthquakes.

Buckling-restrained braces (FIRST braces)

By covering the steel core with buckling-resistant materials, we create high-performance earthquake-proof components that prevent buckling during compression.

Reinforced concrete high-rise technology (the FHRC construction method)

Residential high-rise buildings can be built using reinforced concrete construction, which has excellent heat and sound insulation properties and doesn’t sway much during earthquakes or in strong winds.

The use of ultra-strong concrete for columns, with a compressive strength in excess of 100 N/mm2, creates a smaller cross-section to increase usable living space.

The precast concrete construction method, in which components are made in a factory, achieves higher quality and shorter construction times.

Remote control robots / Robo Q

Recovery activities carried out at the site of debris flow disasters and collapses can be carried out safely and quickly through remote control of construction machinery by human operators from a safe location.

The robot can easily be installed in the driver’s seat of standard construction equipment.

Unmanned Construction Method

Fujita also has a successful track record with other unmanned construction technologies, including remote earthworks systems, unmanned RCC construction, unmanned steel frame construction, and unmanned measuring systems.

SWE-SSRT (Seismic While Excavating SSRT)

This is a technology that conducts continuous, highly accurate surveying of ground conditions up to 300 meters ahead of the tunnel face (the furthest point of the tunnel bore) by conducting a shallow seismic reflection tunnel survey (SSRT) using the tunnel excavation blasts themselves as the seismic wave source.

Measurements both within and outside the shaft are taken continuously with every blast, improving the surveying accuracy.

This process costs less than processes that require a special seismic wave source.

Normally, ground conditions 300 meters ahead of the tunnel face can be analyzed, which provides a margin for changing plans and procuring equipment.

FIRST Brace

The “FIRST Brace” is a Fujita-style Buckling Restrained Brace (BRB), and a highly seismic resistant brace without buckling under compression. The “FIRST Brace” can reduce the number of braces and quantity of structural steel.

Tablet devices on the construction site

This System controls and records how concrete is cast in real time.

Outdoor environmental technologies

Fujita combines multiple technologies to reducing building CO2 emissions

Indoor environmental technology

Combining technologies to implement low-carbon construction and harness natural energy.

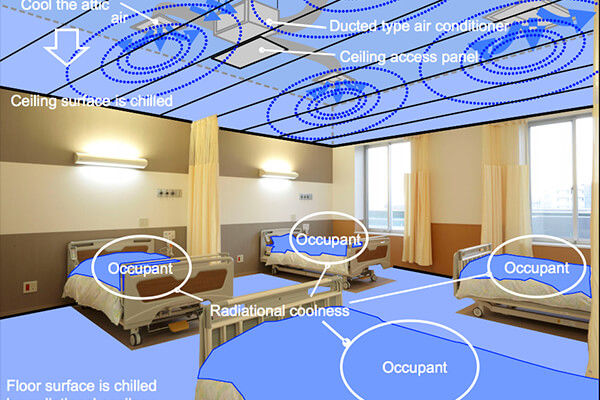

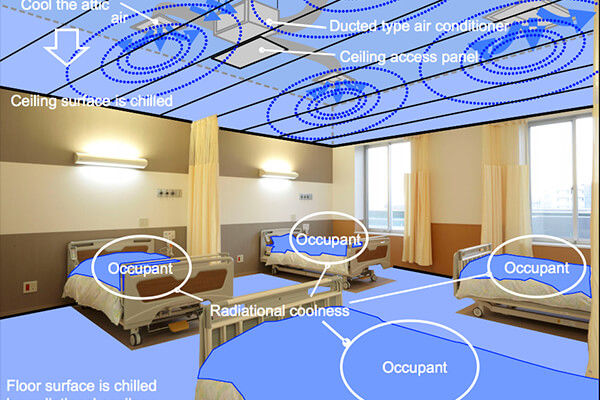

Radiant Cooling and Heating System with Dehumidification

Radiant heating and cooling provides uniform air temperature and reduces energy loss caused by thermal transmission & ventilation

Real World Seismic Response Reduction

A case study showing how response control works during an earthquake

Viscous Damper for Base Isolation and Response Control Systems

Fujita’s Viscous Damper for Base Isolation and Response Control Systems helps protect buildings from earthquakes.

Rainwater harvesting

Rainwater harvesting is an effective way of reducing stormwater runoff and dependency on municipal supplies.

Seismic retrofit

Fujita offers a number of seismic retrofit methods for exiting RC and SRC building, e.g., schools, apartments and offices

Fireproof Glass

By using the thermal insulation glass walls, bright open space can be created and evacuation in case of fire becomes much safer.

Portable Web Camera 360

A 360-degree camera that provides surveillance covering an entire location without any blind spots.

Dual core brace

Seismic support material suitable for use in both high-rise and low-rise construction. The “Dual Core Brace” is a buckling-restrained steel plate with square steel pipes. The “DUAL CORE Brace” is designed in a way so it will not buckle under compression. It can reduce the number of braces and quantity of structural steel.

Energy Monitoring

Our technology enables CO2 levels to be monitored in the real time and provides a detailed understanding of emissions in each process, as well as the opportunity to reduce them.

Visualizing concrete placement in real time

The placing height of concrete is continuously monitored by measurements from a radio type sensor in the mold.

IT Environmental Measurements on Building Sites for Protection of Nearby Residents

Our system constantly measures and monitors the site for problems and ensures safety, even in the event of earthquakes and other disasters.

Active Noise Control

ANC system reduces low frequency sounds using the wave nature of sound

Environmentally-friendly solutions

Fujita has proposed plans for new construction and for facility maintenance and energy efficiency retrofits to reduce emissions of CO2.

Seismic retrofit for factories

The Fujita retrofit method for factories (FSR-D method, WT clamp method) shortens the construction by reducing the need welding work.

Camera system for Concrete Filled Tube

CFT is a pillar structure comprising a steel tube filled with concrete. The CFT camera is the device which can provide pictures and precise measurements in real time on a PC.

Drum Silencer for Reducing Tunnel Blasting Sound

A “Drum Silencer” sound absorption system with sound insulation doors can reduce ultra-low frequency sounds produced by blasting in mountain tunnel excavation. The layout of the drums can be changed depending on working conditions within the tunnel.

Tablet devices on the construction site

This System controls and records how concrete is cast in real time.

Conservation of biodiversity

When we design and plan construction, we attempt to reduce impacts on the natural environment and local fauna and flora. We try to conserve rare species.

KPOD for evaluating radioactive soils

With the aid of a simulation system (K.POD), allows consistent evaluation of radioactively contaminated soils, design of the concrete shielding containers and post-shielding monitoring.

High Capacity Micro Pile

High capacity micro piles (HMP) combine the drilling technology used by the ground anchor method and the pressurizing injection technology of grouting.

Embankment Renewal Technology

Embankments are strengthened so as not to be destroyed by tsunami overtopping.

Ultra-long-distance remote control unmanned construction

A development of Fujita’s unmanned construction technology using mobile phone networks over distances > 1000km

Portable Web Camera 360

A 360-degree camera that provides surveillance covering an entire location without any blind spots.

FT Madokira

A porous soil improvement material made from paper sludge ash with high swelling ability, FT MADOKIRA can improve mud through mixing without needing time to cure.

Energy Monitoring

Our technology enables CO2 levels to be monitored in the real time and provides a detailed understanding of emissions in each process, as well as the opportunity to reduce them.

Visualizing concrete placement in real time

The placing height of concrete is continuously monitored by measurements from a radio type sensor in the mold.

IT Environmental Measurements on Building Sites for Protection of Nearby Residents

Our system constantly measures and monitors the site for problems and ensures safety, even in the event of earthquakes and other disasters.

Active Noise Control

ANC system reduces low frequency sounds using the wave nature of sound

Conservation of biodiversity

When we design and plan construction, we attempt to reduce impacts on the natural environment and local fauna and flora. We try to conserve rare species.

Effective utilization of organic waste

Technologies to convert organic waste into energy and biomass

Outdoor environmental technologies

Fujita combines multiple technologies to reducing building CO2 emissions

Indoor environmental technology

Combining technologies to implement low-carbon construction and harness natural energy.

Radiant Cooling and Heating System with Dehumidification

Radiant heating and cooling provides uniform air temperature and reduces energy loss caused by thermal transmission & ventilation

Radiation Decontamination and Salt Removal (East Japan Earthquake)

Following the great East Japan earthquake, Fujita has been actively involved in rehabilitation of agricultural land.

Management of Disaster Waste Disposal (East Japan Earthquake)

Following the great East Japan earthquake, Fujita was actively involved in disposal of disaster waste.

Response of Fujita Corporation to the Great East Japan Earthquake

Out of a collective sense of responsibility felt by the Construction Industry, Fujita began reconstructing public infrastructures and private buildings immediately after the quake

Rainwater harvesting

Rainwater harvesting is an effective way of reducing stormwater runoff and dependency on municipal supplies.

Phytoremediation

Phytoremediation is a low-cost, environmentally-friendly technology for cleansing soil contaminated with heavy metal.

Environmentally-friendly solutions

Fujita has proposed plans for new construction and for facility maintenance and energy efficiency retrofits to reduce emissions of CO2.

FAST system for pretreatment of Incineration Bottom Ash

A simple pretreatment system for incineration bottom ash using water and aeration.