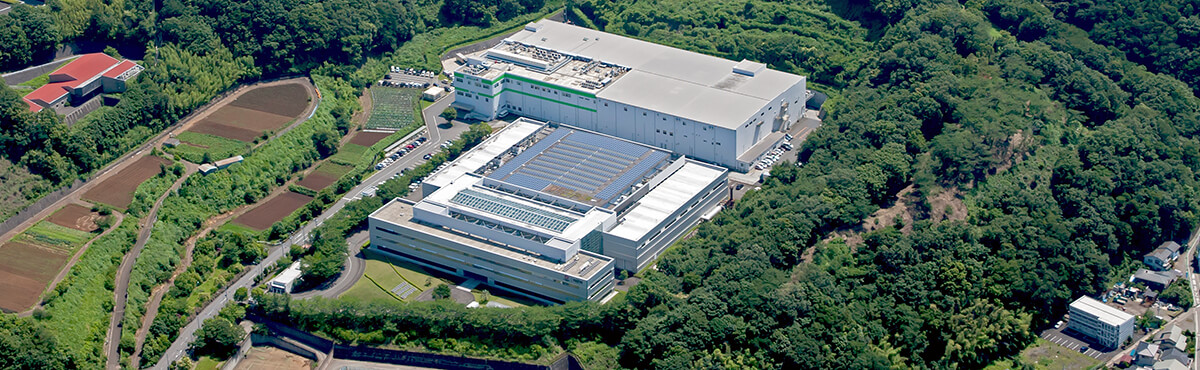

Fujita Technology Center - a test-bed for new technologies

Technical center mission

The Technology Center isn’t just the place where we invent new technologies. It’s the place we first put them into practice in a real building – ours. The mission of the center is:

- R&D in response to social needs into:

Building construction technology, Civil engineering, Environment and IT - Verification and asessment of newly-developed technologies

- Commercialization of new technologies

- Presentation of new technologies to clients

Features

Our technology center is a physical manifestation of Fujita’s commitment to our environment. Over the years we’ve added many features to carefully test their performance in the real world.

Floor Vibration Control using Tuned Mass Dampers (TMD)

A vibration control device consisting of “Mass (Weight)”, ”Spring” and “Damper (damping device)” and is called the “TMD (=Tuned Mass Damper)”.

Rooftop greening

Urban greening aims to reduce heat-island effects, improve the heat insulation capacity of buildings for energy saving and protecting the natural environment.

Photovoltaic power

Fujita provides low cost and rapid installation PV using Solar Base

Response Control System

Response control devices installed on buildings reduce the response of the building during an earthquake. Panel dampers and viscous dampers were installed in the Fujita Technical Centre.

Base Isolation System

Base isolation devices make it hard for earthquake vibrations to transfer to a building. Rubber bearing isolator etc. were developed as the device.

Fire-resistant Glass Door and Partition

Stairway walls and doors are made of fire-resistant glasses. These installations increase design freedoms such as cost reduction, architectural design and fire-resistant performance.

Facilities

Test facilities in our technology center include:

Wind tunnel facilities

This wind tunnel can simulate various interactions between wind and buildings over a wide range of windspeeds, allowing us to identify the cause of observed phenomena and to devise techniques to overcome them. The dimension of the wind tunnel are 3m in width, 1.8m in height and 22m in length. The maximum wind velocity is 25m/sec. This wind tunnel can evaluate wind patterns around buildings, design wind load for exterior materials, and predict vibration characteristics of buildings.

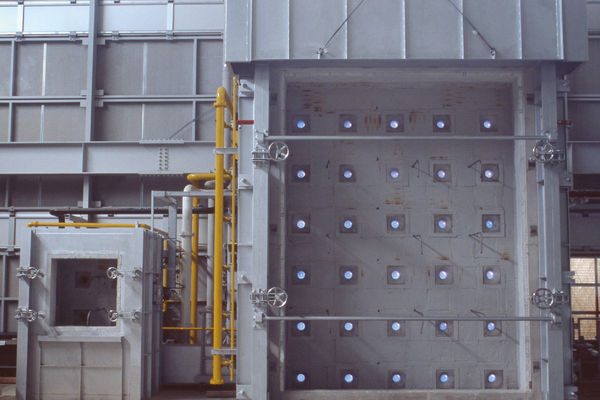

Fire Resistance Testing Furnace Facility

Facility for testing fireproof performance of building materials. The facility is constructed to allow use of the testing method “ISO-834 Fire-resistance tests” (which follows performance based rules of revised “Building standard low in Japan”). In this facility, there are three furnaces as follows;

Multi-purpose furnace : Floor dimensions are 3m in width, 4m in height and 6m in length, with 1000tf of maximum loading force.

Large scale furnace for wall : The dimensions are 3m in width, 4m in height , with 20tf of maximum loading force.

Small scale furnace : The dimensions are 1m in width and 1m in height.

Abutment Wall and Floor Test Facility

This facility can examine the safety of structures by testing ultimate capacities and stiffness (covering the elasto-plastic stress regions) for full scale (or nearly full scale) specimens. The abutment wall has dimensions of 10m in height and 13m in width, and the maximum bending moment is 16,000 tfm and the maximum shearing force is 4,000 tf. The floor has dimensions of 20m in length and 25m in width.

Structural testing facility - reaction slab / reaction wall

This facility can help ensure the safety of structures by testing ultimate bearing capacities and stiffness for full scale (or nearly full scale) specimens using a reaction wall and reaction slab.

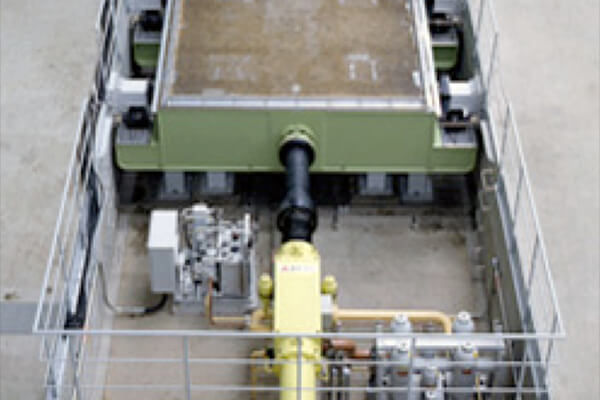

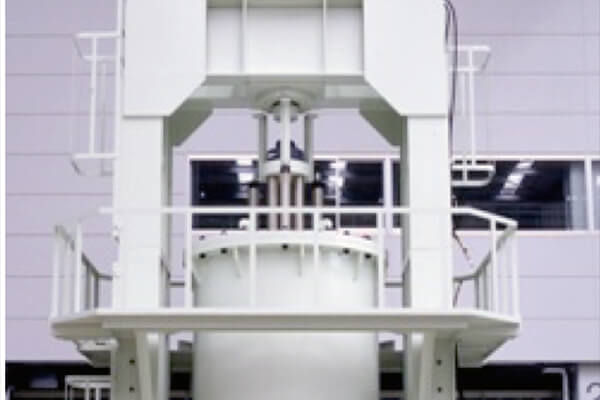

Large-scale vibration table

The large-scale vibration table is equipped to allow various experiments in designing safety features for buildings and planning comfortable housing. The dimensions of the vibration table are 4m in length and 4m in width. The maximum weight applied to the table is 25tf, and a one-dimensional horizontal wave can be applied. The maximum vibration displacement is 500mm, the maximum velocity is 150 cm/sec; the maximum acceleration is 1G at the maximum loading.

Acoustic Experiment Facility

This facility consists of “Anechoic room” and “Reverberation room”.

The anechoic room is acoustically isolated by sound absorbing material on all surfaces, so there is no sound reflection. In this room, scale model sound transmission tests, auditory sense tests and sound power level measurements are possible. The room dimension is 6.3m in width, 11.5m in length and 9.2m in height. The cutoff frequency is 90 Hz.

The coupled reverberation rooms are surrounded by concrete wall, so that any sound can spread uniformly with less energy decrease. Sound absorption tests and sound insulation tests of building materials are available, and noise source characteristics can also be measured.

Electromagnetic Environment Experiment Facility

The main role of the anechoic chamber (constructed to FCC-3m regulations) is to measure electromagnetic wave accurately.

The magnitude and noise level of electromagnetic wave produced by electronic devices are measured in this room. In the shielded room, the measurement of electromagnetic wave and magnetic field are carried out with high precision.

Concrete Materials Experiment Facility

This facility houses equipment for testing materials, mixing, strength and durability of concrete. Available apparatus includes a freezing and thrawing test machine, constant temperature and moisture rooms, a universal testing machine, a neutralization acceleration testing machine, and an adiabatic temperature testing machine.

Finishing Material Experimental facility

The main roles of this facility are the performance evaluation, and analysis and development of new finishing materials for buildings.

An electron microscope and a X-ray analyzer in the facility enable microscopic analysis of finishing materials.

Also, a constant temperature and humidity room, an endurance testing apparatus (for sunshine, xenon, ozone, salt spray and so on) are also available.

Environmental Experiment Facility

This facility is used for experiments in purification of pollutants, environmental protection and use of renewable energy. By using ICP-emission spectral analysis equipment, mass spectrometer and scanning electron microscope, environmental research and chemical analyses for air, water and soil quality can be performed. There are also laboratories for evaluating performance of purification techniques and for plant cultivation.

Indoor Environment and Building Services System Experiment Facility

This facility is used for experiments and evaluations in indoor environment and building services system.

By using air flow experiment space and heat source equipment, various experiments can be made as follows;

- (1)HVAC

- (2)Thermal storage and heat flow

- (3)Cleanroom

- (4)Ventilation aeration

- (5)Smoke diffusion

- (6)Lighting

- (7)Physiological-psychological response

Large-scale Triaxial Compression and Plain Strain Test Apparatus for Grain Soils

Apparatus for testing the stress-displacement relationship of coarse grain soils, used mainly for embankment of fill dams. This apparatus can obtain stress-deformation characteristics for soil structures in-situ. Specimen dimensions are 1000mm in diameter, 2000mm in length for triaxial test, 920mm in length, 800mm in width and 1600mm in height for plain strain test. The maximum axial force is 300tf and the maximum lateral pressure isσ3 = 8 kgf/cm2.

High-stiffness Triaxial Compression Test Apparatus for Rock

Apparatus for testing rock strength at the overburden depth of up to 3,000m. This apparatus has a high-stiffness loading system allowing measurements of the stress-strain relationship after the elastic limit. The maximum compression force is 100 tf.

Hydraulic Test Apparatus

Two dimensional test tank for simulation of ocean waves and river flow. By using a computer controlling system, both regular and irregular waves (up to approximately 30 cm in height) can be generated, and flow volumes of 100 litre per second controlled at the same time. The dimensions of pit are 50m in length, 1m in width and 1.5m in height.

General information

| Address | 2025-1 Ono, Atsugi City , Kanagawa 243-0125, Japan |

|---|---|

| Site area | 28,500sq.m / 307,000 sq.ft |

| Zoning | Semi-industrial area |

| Building area | 10,900sq.m / 117,000sq.ft |

| Total floor area | 24,150sq.m / 260,000sq.ft |

| Laboratory building | 3 storeys – RC + S (base-isolated structure) |

| Experimental hall | 3 storeys – S (seismic control structure) |