Development of a system to reduce ultra-low frequency tunnel blasting sound by recycled drums as sound absorption equipment

Fujita Corporation

President: Yoji Okumura

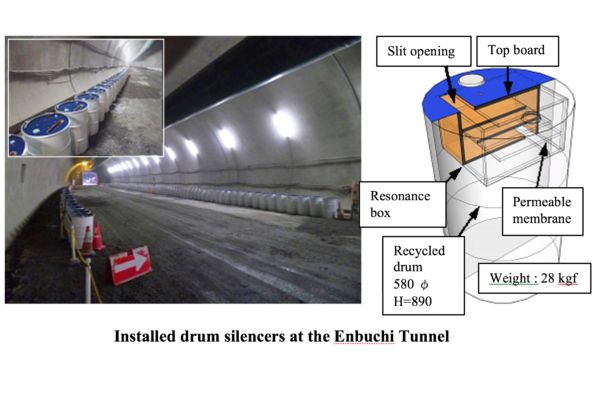

Fujita Corporation, a Daiwa House Group company (Headquarter: Shibuya-ku Tokyo, President: Yoji Okumura) has developed a " Drum Silencer" sound absorption system to reduce ultra-low frequency sounds produced by blasting in mountain tunnel excavations, and applied the technology to our "Enbuchi Tunnel Project" (Soma-city, Fukushima Prefecture, Japan). This system can reduce ultra-low frequency sounds, which are very difficult to mitigate by using conventional sound insulation doors at tunnel entrances, by using silencer equipment mainly composed of recycled drums installed within the tunnel.

The blasting sound, produced when tunnels are excavated, includes ultra-low frequency sounds. Usually, sound insulation doors are installed at a tunnel entrance to cut the sound. However, sound insulation doors cannot sufficiently reduce sounds in the10-20 Hz range, even if the door weight is increased by adding concrete. Although these strong ultra-low frequency sounds are inaudible to humans, they are transmitted through the doors, and can cause vibrations in glass windows and fittings in houses near the tunnel.

In order to solve this problem, we have developed a sound absorption system "Drum Silencer" that dampens the ultra-low frequency sound. The system uses recycled, lightweight open-head typed drums that can withstand air blasts. A slit opening is put on a top board, and a resonance box is installed in the drum. By adopting the structure, the system can be drastically downsized compared with conventional blasting sound absorption equipment. In the drum, sound waves that pass through the slit opening vibrate the air within the resonance box, changing vibration energy to heat energy. By changing the opening area on the top board and the shape of the resonance box, the absorption characteristics can be adjusted and the sound absorption performance can be tuned to harmonize the sound absorption characteristics of the sound insulation doors.

At the excavation site of the Enbuchi Tunnel, 200 drums were installed in the tunnel, and it was confirmed that the ultra-low frequency sound level was reduced by up to 7 db. From this result, the leakage of the ultra-low frequency sound can be highly reduced by combining the conventional sound absorption performance of the doors with the "Drum Silencer".

The light and downsized "Drum Silencer" can be installed at the early stages of tunnel excavation when the installation space is tight, and the layout of the drums can be changed depending on working conditions within the tunnel, because the sound absorption effect of the system can be obtained regardless of installation location and layout. From now on, the system will be pro-actively installed in our tunnel excavation sites using the blasting method to promote our environmental approach to effective use of recycled resources and our consideration for the surrounding environment.

---

ENDS

---

Fujita Corporation

Public Relations Office

Tel. +81-3-3402-1911

Fax. +81-3-3404-8477

Email. info@fujita.co.jp