Joint Development of a Heavy Machinery-Mounted Laser Scanner - 3D Shape Measurement: Enhanced Productivity through "i-Construction" -

Fujita Corporation (headquarters: Shibuya-ku, Tokyo, President: Yoji Okumura) of the Daiwa House Group has developed a heavy machinery-mounted laser scanner for use in earthwork shape measurement in cooperation with Geosurf Corporation (headquarters: Minato-ku, Tokyo, President: Masayuki Uchiyama). This system uses a heavy machinery-mounted laser scanner (hereafter LS) that can obtain planar shape coordinates as it moves to random locations during operation. Since the conventional laser transits were disadvantageous in time required for relocation and setup, we have highly anticipated for a technology that allows to measure its own position at high accuracy while moving.

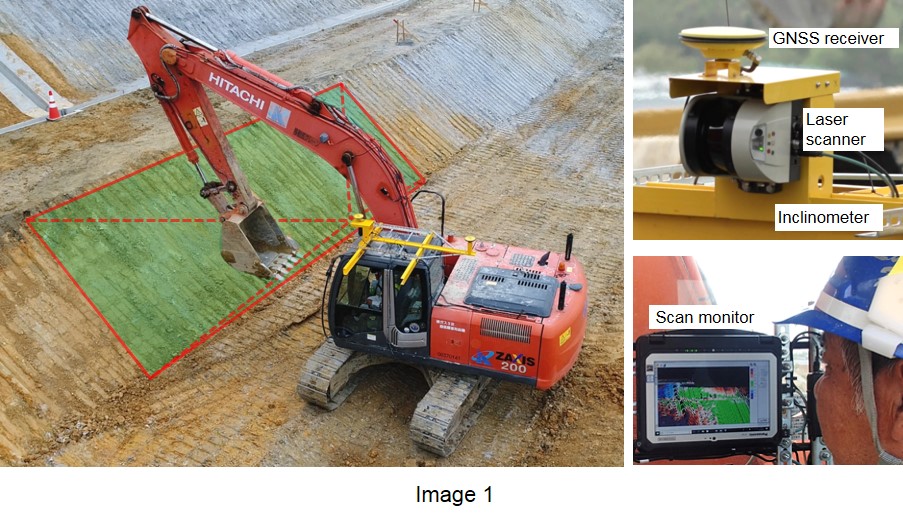

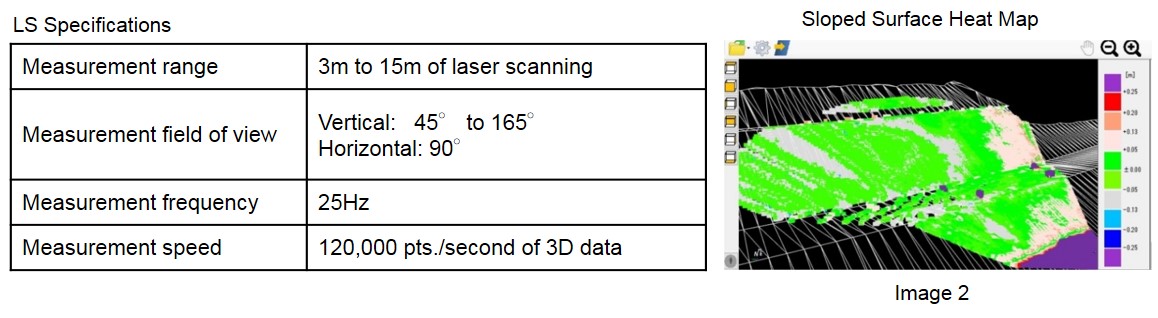

This system consists of a LS and a GNSS *1 receiver, inclinometer and a scanner monitor (Image 1). When the operator presses the SCAN button from the driver's seat, the heavy machinery rotates to scan within the measurement range to acquire and calculate various data: the GNSS for position coordinates, the LS for the distance to the work surface and the inclinometer for the heavy machinery's balance. These results are then converted to the current point clouds. By superimposing this data on 3D design data and displaying a multi-colored heat map (Image 2), the current conditions can be compared against the design to easily calculate if more earth must be removed or filled. This point cloud data can also be imported into a dedicated software for heat mapping to display multi-colored measurement points for comparison and conformity to the standard values.

*1 Global Navigation Satellite System

There has been remarkable progress in earth work over the recent years, such as construction machinery ICT (Information and Communication Technology) that enables inexperienced operators to perform work equivalent to seasoned workers. However, the current ICT simplifies the operation only by displaying the position of the teeth to assist the machine operator to not exceed the designed line. This does not make clear of the entire work surface variation in comparison to the design, thus still requires tape measures and levels to confirm the accuracy of the shape during construction. Additionally, the shape is measured and analyzed after the completion by tripod-mounted LS transits or conventional UAVs* . This conventional method costs large amount of time, labor, and did not allow real-time analysis.

On the other hand, this system allows measurement immediately after the work on the operator's discretion to determine the quality in real-time; thereby contributing to improved quality and productivity through prompt rework in case the results are unacceptable.

*2 Unmanned Aerial Vehicle

System features

1. A versatile and universal system that uses inexpensive outdoor-type 2D LS to acquire 3D data by simply rotating the heavy machinery, whereas the 3D LS can be more expensive and less durable.

2. Laser scanning can be partially run as per work progress to acquire simplified calculation of a wide ranging surface.

3. Easy to mount on the exterior of a heavy machinery. Scanning is operated from the touchscreen at the driver's seat.

4. Unlike UAV surveys, free from impact due to the work environment such as heavy wind or rain, as well as varying terrain conditions.

5. Improved earthwork productivity through considerable reduction of survey work due to the shortened scan time.

Test Result

This system was introduced and accuracy tested in Tokiguchi development and land reclamation work ordered by Tokiguchi Zaisanku, Toki City, Gifu Prefecture. The results satisfied the standard shape measurement values set forth by the Ministry of Land, Infrastructure, Transport and Tourism on a -/+50mm accuracy for the measurement range of 15m. By integrating this measurement data with ICT-equipped construction machines, land surveys will be more efficient, accurate and simple, resulting in enhanced productivity.

This technology can also be applied to construction work management of dams and tunneling works in addition to general earth work. Fujita Corporation aims to further upgrade this feature with vision towards this technology to various applications.

---

ENDS

---

Fujita Corporation

Public Relations Office

Tel. +81-3-3402-1911

Fax. +81-3-3404-8477

Email. info@fujita.co.jp