Development of a system to reduce tunnel blast noise -Reduction of all frequency bands through a combination of systems-

Fujita Corporation (headquarters: Shibuya-ku, Tokyo, president: Yoji Okumura) of the Daiwa House Group has combined two countermeasure technologies with different target frequencies as the second step to prevent blast noise in residential areas nearby mountain tunnel construction, developing a system that efficiently reduces blast sound as needed for the excavation stage.

Blast excavation is performed multiple times a day regardless of whether it is day or night and causes very loud noise. The sound across all frequency bands is an issue in the early stages of excavation, while as distance of the excavation extends, audible sound is attenuated but low-frequency sounds stand out. As a result of characteristics that differ depending on the stage of excavation, countermeasures to reduce blast sound for those living in the vicinity is c technologically difficult.

Therefore, after developing the Drum Silencer*, which absorbs ultra-low frequency sound during tunnel blasting, Fujita Corporation developed a Tube Cell Silencer which uses existing tunnel facilities to counter sounds exceeding 100Hz. In addition, an Active Target Silencer was also developed that inverts sound phase to mask sounds below 100Hz that homes around the tunnel are subjected to Fujita Corporation verified these during in-house tunnel construction, confirming a 10dB reduction in noise (audible sound) and a 6dB reduction at low frequency through combined use of both systems. This, along with the Drum Silencer, enables effective reduction of blast sound on all frequency bands.

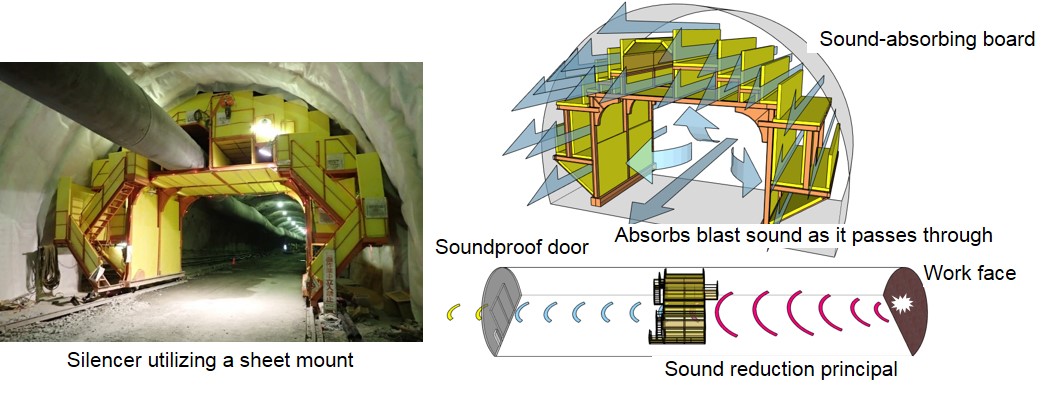

Tube Cell Silencer

A silencer was created that reduces audible sound by attaching a sound-absorbing board to work equipment such as a water-proof sheet mount or other vehicle set up within the tunnel. This effectively reduces sound in the 100 to 500Hz band by 4 to 6dB, and sound at or above 500Hz by 3dB. After use as a silencer to handle audible initial excavation sound, it can then be used as normal work equipment. Because existing facilities are used, cost is reduced and work inside the tunnel is not impeded.

Verification Site

・Takamatsu Expressway, Tsuda Tunnel construction (Ordered by: West Nippon Expressway Company, Shikoku Branch)

・Nagasaki Expressway, Hirama Tunnel Construction (Ordered by: West Nippon Expressway Company, Kyushu Branch)

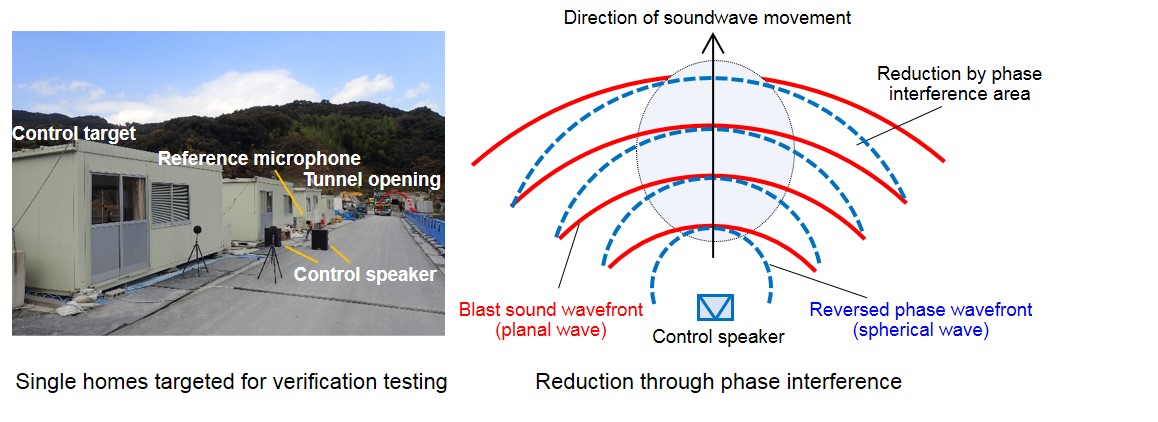

Active Target Silencer

During blast excavation, a microphone picks up sounds transmitted to target homes at the tunnel surface, instantly analyzing and playing the reverse of the sound to cancel the sound of the blast. Compared to tunnel opening control, the controlled area had fewer speakers placed and better suppressed output. When controlling low frequency sounds of 100Hz or less at a point 100m away from the opening, reductions of 5 to 10dB were obtained within an a one-speaker area of approximately 10 x 20m. Increasing the number of placed speakers widened the reduction area, so by checking blast sound characteristics, distance from the tunnel opening and the conditions of the target area in advance, an optimal control system can be planned and constructed.

Verification Site

・Nagasaki Expressway, Hirama Tunnel Construction (Ordered by: West Nippon Expressway Company, Kyushu Branch)

・Nagasaki Expressway, Nakao Tunnel Construction (Ordered by: West Nippon Expressway Company, Kyushu Branch)

Fujita Corporation will actively utilize findings obtained during blast excavation tunnel construction in the future and promote initiatives in consideration of the on-site sound environment.

* Drum Silencer

Development technology we announced on June 24, 2016.

Development of a system to reduce ultra-low frequency tunnel blasting sound by recycled drums as sound absorption equipment

---

ENDS

---

Fujita Corporation

Public Relations Office

Tel. +81-3-3402-1911

Fax. +81-3-3404-8477

Email. info@fujita.co.jp