Fit-crete confirmed to prevent cracking in concrete; use in actual buildings being promoted

Fujita Corporation (head office: Shibuya-ku, Tokyo; President: Yoji Okumura), a company in the Daiwa House Group, jointly developed technology to limit concrete drying shrinkage to a range of 0-800×10-6*1. The technology was developed jointly with six other companies: Hazama Ando Corporation (head office: Minato-ku, Tokyo; President: Masato Fukutomi), Kumagai Gumi Co., Ltd. (head office: Shinjuku-ku, Tokyo; President: Yasunori Sakurano), Sato Kogyo Co., Ltd. (head office: Chuo-ku, Tokyo; President: Masafumi Miyamoto), Toda Corporation (head office: Chuo-ku, Tokyo; President: Masanori Imai), Nishimatsu Construction Co., Ltd. (head office: Minato-ku, Tokyo; President: Nobutoshi Takase) and Maeda Corporation (head office: Chiyoda Corporation, Tokyo; President: Soji Maeda).

A concrete product called Fit-crete has been produced based on this technology, and a trademark application is pending. The cracking prevention effect of the drying shrinkage reduction method was confirmed through a two-year exposure test of two types of full-scale specimens made of Fit-crete, and Fit-crete is now being used in actual buildings.

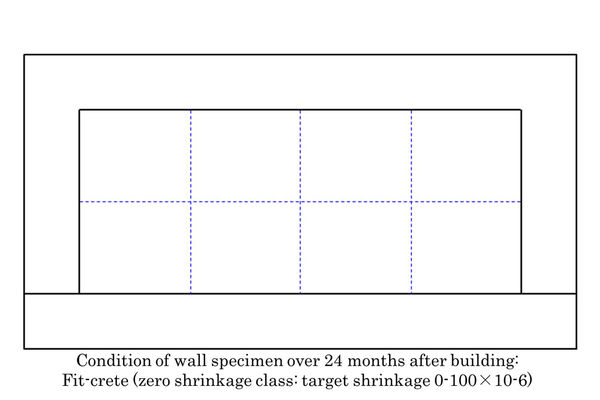

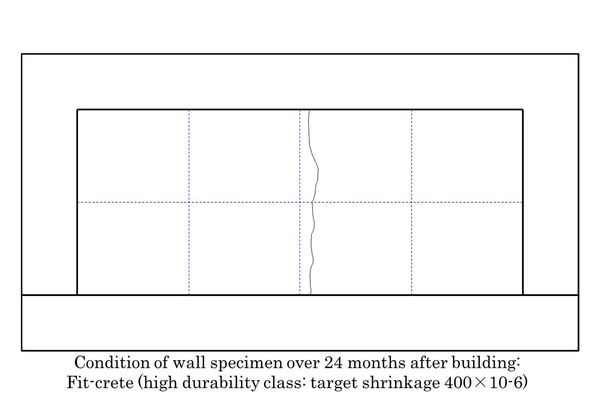

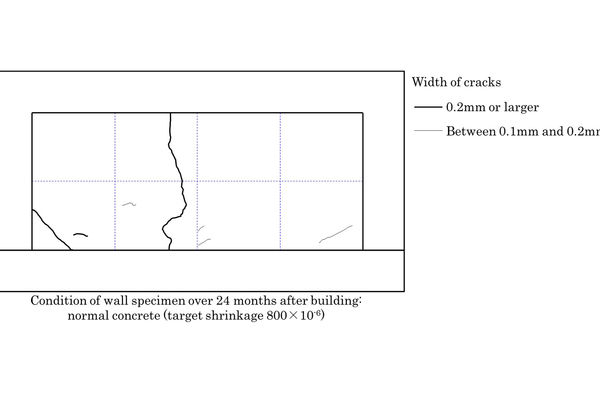

The results of the two-year experiment indicated that cracking was reduced proportionately to drying shrinkage prevention, with no cracking in the exterior of the specimens made from the zero shrinkage class of Fit-crete.

Thus far, the zero shrinkage class of Fit-crete has been used in two buildings, a low shrinkage class that reduces drying shrinkage to around 250×10-6 has been used in two buildings, and a high durability class that reduces drying shrinkage to around 400×10-6 has been used in many buildings. Application in many more buildings is planned, and Fujita Corporation and six other companies are promoting even wider use to ensure higher concrete quality in future.

1. Results of verification of cracking prevention using full-scale specimens

In 2015, the seven participating companies established and proposed methods to reduce drying shrinkage in concrete to a range of 0 to 0-800×10-6 using a coarse limestone aggregate, a shrinkage reducing agent and an expanding material produced in various regions. The effect of drying shrinkage prevention in reducing cracking in concrete was verified by building full-scale wall specimens and RC slab specimens with a steel deck and conducting an outdoor exposure test for two years.

A comparison of the length of cracks in the wall specimens by square meter indicated that the high durability class, which reduces drying shrinkage to around 400×10-6, reduced cracking by around 77% compared to concrete with no measures implemented. No cracking at all occurred in the exterior made from the zero shrinkage class.

For the specimens of RC slabs with a steel deck, cracking only occurred in the specimens made from ordinary concrete. None occurred in the specimens made from the high durability class or low shrinkage class.

This proved that the drying shrinkage control method used in the concrete of the full-scale specimens was effective in reducing cracking in concrete. The new concrete was named Fit-crete (trademark application pending), and there are plans for further popularization.

*1: Change in length (example): 800×10-6 = 0.8mm shrinkage in 1m-long concrete structure.

2. Application of Fit-crete in actual buildings

Proposals and discussions for the use of Fit-crete in various buildings have been carried out since this drying shrinkage control method was established in 2015. The zero shrinkage class of Fit-crete has been used in two buildings (fair-faced concrete walls in a research facility and an educational facility), the low shrinkage class has been used in two buildings (the outer wall of an office building and the floor slabs of a logistics facility) and the high durability class has been used in many buildings. Each has shown strong cracking prevention performance, and discussions are currently underway to use the zero shrinkage class in another building.

3. Future developments

Fujita Corporation and six other companies plan to actively propose Fit-crete as a solution that will provide optimal concrete performance to meet the requirements of concrete structures such as exposed structures that require a beautiful exterior for exposed concrete structures, the floors of warehouses and factories, and buildings that require a strong shielding performance.

The company also aims to use the data obtained from the testing of the full-scale specimens to find the optimal design methods to reduce drying shrinkage, and establish and propose quality verification methods.

Reference

Summary of Drying Shrinkage Control Technology

Below are the drying shrinkage definitions (target values) for the control methods that were developed.

・High durability class: Target drying shrinkage around 400×10-6

・Low shrinkage class: Target drying shrinkage around 250×10-6

・Zero shrinkage class: Target drying shrinkage around 0-100×10-6

Combinations used in full-scale specimens

| Concrete type | Target drying shrinkage (x10-6) | Materials used | Full-scale specimens | |||

| Expanding material | Shrinkage reducing agent | Coarse aggregate | Wall | Deck slab | ||

| Ordinary concrete | 800 | - | - | Tight sands | ✓ | ✓ |

| High durability class | 400 | ✓ | - | Limestone | ✓ | ✓ |

| Low shrinkage class 1 | 250 | ✓ | ✓ | Limestone | - | ✓ |

| Low shrinkage class 2 | 250 | ✓ (more than high durability class) | - | Limestone | - | ✓ |

| Zero shrinkage class 2 | 0-100 | ✓ | - | Limestone | ✓ | - |

To verify the effects, full-scale wall and deck slab specimens were made from five types of concrete from the zero shrinkage class to ordinary concrete. These were measured over a long period of time beginning in October 2015.

---

ENDS

---

Fujita Corporation

Public Relations Office

Tel. +81-3-3402-1911

Fax. +81-3-3404-8477

Email. info@fujita.co.jp