Development of a non-scaffold construction method for installing outer wall panels

Daiwa House Industry CO., LTD (Headquarter : Osaka-city, President : Keiichi Yoshii, hereinafter referred to as "Daiwa") and Fujita Corporation (Headquarter: Shibuya-ku, Tokyo, President: Yoji Okumura, hereinafter referred to "Fujita") have developed a new "Metal sandwiched panel for outer wall" and a "Non-scaffold construction method for installing outer wall panel provisionally called "NoScaUP (Non-Scaffold Unit Panel) Method)" in collaboration of Nippon Steel & Sumikin Coated Sheet Corporation (Headquarter : Chuo-ku,Tokyo, President : Seiji Hosogai, hereinafter referred to as "NICS").

In Daiwa House Group, in order to solve problems with shortages of engineers and to improve the work environment, new technologies for productivity improvement such as labor-saving construction methods and methods for shortening the construction period have been developed. For these reasons, in 2013 Daiwa and Fujita started the development of the method aiming at deploying the method in large-scale construction sites. As a result, by using this method, the number of workers necessary for installing outer wall panels can be reduced by up to 30%.

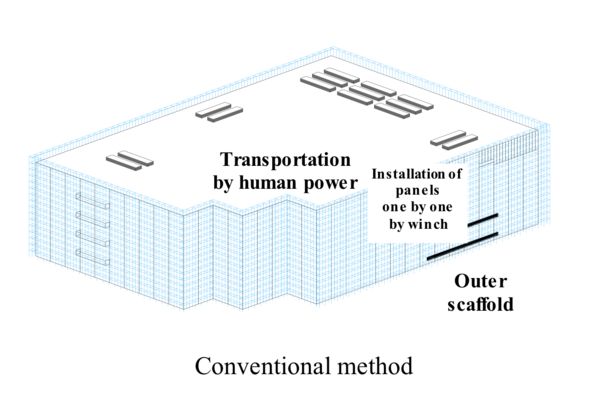

In general, when outer wall panels are installed at construction sites such as logistics facilities and factories by using conventional outer scaffolding method, outer scaffolds have to be assembled and panels are installed one by one. However, assembling and disassembling of the outer scaffolds requires many workers and working days.

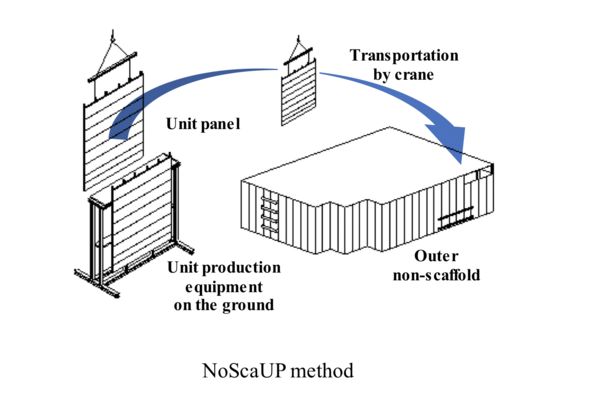

To solve these problems, "Daiwa" and "Fujita" have developed the "NoScaUP Method"

with collaboration of "NICS". By using the method, outer scaffolds are not necessary, and outer sandwiched panels are installed from inside the structure (indoor installation is possible).

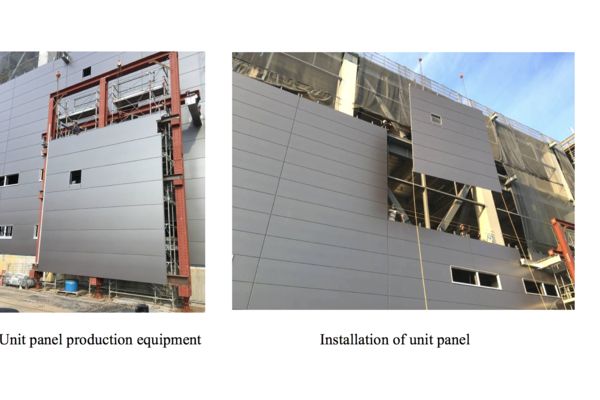

Using this method, several panels are connected into a unit panel on the ground, and these units are lifted by a crane and installed onto a framework (building). At a construction site for a logistics facility construction (completed by Fujita in February 2018), the method was adopted and the productivity improvement for outer wall panels installation was verified.

In the future, to solve serious labor force shortage problems, "Daiwa" and "Fujita" will deploy the developed metal sandwiched panels and "NoScaUP Method" at large-scale facilities projects. "Daiwa" and "Fujita" will make more efforts to realize productivity improvement and working environment improvement such as five-day workweek system.

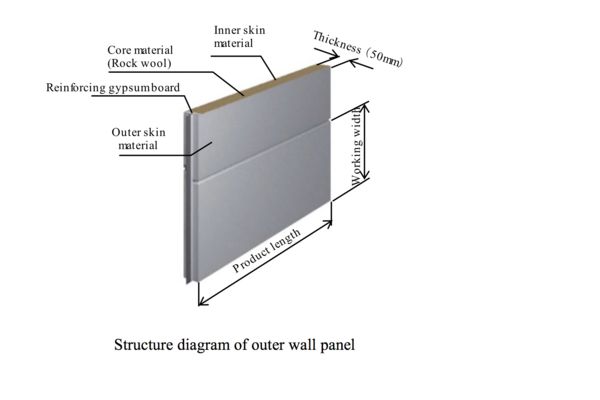

In "NoScaUP" method, the newly developed outer wall panel is used. This panel has a sandwiched structure and core material (rock wool) is put between restraint members (steel plate). This panel has weight: 20kgf/m2, height: 600 - 1000 mm, thickness: 50 mm, length: maximumly 10 m, and is certified as "30 minutes and one hour" fireproof material.

---

ENDS

---

Fujita Corporation

Public Relations Office

Tel. +81-3-3402-1911

Fax. +81-3-3404-8477

Email. info@fujita.co.jp