Development of new drying shrinkage strain control technology in concrete structures and verification of the crack reducing effect

Fujita Corporation

President: Yoji Okumura

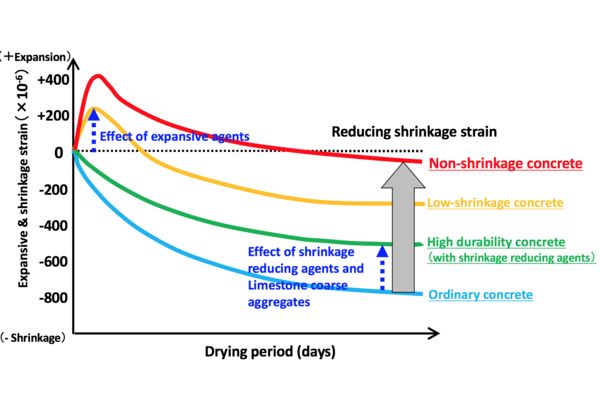

Fujita Corporation (Headquarter: Shibuya-ku Tokyo, President: Yoji Okumura) has jointly developed a new drying shrinkage strain control technology in concrete structures with Hazama Ando Corporation (Headquarter: Minato-ku, Tokyo, President : Toshiaki Nomura), Kumagai Gumi Corporation (Headquarter : Shinjuku-ku, Tokyo, President : Kiyoshi Higuchi), Sato Kogyo Corporation (Headquarter: Chuo-ku Tokyo, President: Masahumi Miyamoto), Toda Corporation (Headquarter: Chuo-ku Tokyo, President: Masanori Imai), Nishimatsu Construction Corporation (Headquarter: Chuo-ku Tokyo, President: Harusada Kondo), Maeda Corporation (Headquarter: Chiyoda-ku Tokyo, President: Soji Maeda). The technology can control the drying shrinkage strain in concrete within 0 - 800 × 10 -6.

1. Background

Cracks caused in concrete by drying shrinkage strain affect the durability and the appearance of the concrete structures. Client requests for crack reduction have been increased and construction companies have tried various techniques to solve the problem.

The "Japanese Architectural Standard Specification for Reinforced Concrete Work JASS5" (issued by the Architectural Institute of Japan) specifies that the concrete dry shrinkage factor should be within the range of 0 - 800 × 10-4 for long-term and ultra-long-term material age. In order to meet this specification, material selection and formulation have been examined in detail. For example, coarse limestone aggregate is used together with drying shrinkage reducing agents and expansive agents are used. However, there are still problems to be solved. For example, simultaneous uses of drying shrinkage reducing agents and expansive agents and different types of cement have significant influence on drying shrinkage strain and strength in concrete.

2. Characteristics of the developed technology

During the development process, the combination and volume of drying shrinkage reducing agents and expansive agents as well as influence caused by the different types of cement are examined in laboratory tests. As a result, we have identified formulations that can reduce the drying shrinkage strain to within the 0-800 ×10 -6range.

Characteristics of the strain control technology are as follows;

(1) Limestone coarse aggregate, drying shrinkage reducing agents and expansive agents are used.

(2) The combination of materials and adjustments of material volume are the keys of the technology

(3) The materials used can be selected depending on: required performance, locality (usable aggregates) and materials which can be supplied to local concrete factories.

Targeted strain levels are as follows;

(1) High durability concrete : < 400 ×10 -6

(2) Low shrinkage concrete : < 250 ×10 -6

(3) Non-shrinkage concrete : within 0-100 ×10 -6

3. Results of full-scale tests

In order to verify the effectiveness of the technology to reduce and control the drying shrinkage strain in concrete, five types of concrete (with strain levels varying from zero to normal) were formulated, and full-scale test structures for walls and deck slabs were prepared by casting the different concrete formulas. In the six months following the concrete casting no drying shrinkage strain has been observed in the test concrete structures.

4. Cost comparison

Compared with the cost of the ordinary concrete, the costs of concretes formulated using the developed technology are as follows;

(1) High durability concrete : ca. 1.3x more expensive than ordinary concrete

(2) Low shrinkage concrete : ca. 1.5x more expensive than ordinary concrete

(3) Non-shrinkage concrete : ca. 2x more expensive than ordinary concrete

The cost differs depending on the types and volume materials used, however, the most suitable formulations can be selected according to budget and required performance.

5. Future developments

By using concrete formulated using our new technology, we can provide our

clients with concrete structures that look great and have long-term durability. In particular it will allow us to provide concrete for the floors of factories and warehouses and undressed concrete floors for RC structures.

Visual inspections for cracks and long-term strain measurements will continue for two years, and further improvements of the developed technology will be implemented based on the results obtained.

---

ENDS

---

Fujita Corporation

Public Relations Office

Tel. +81-3-3402-1911

Fax. +81-3-3404-8477

Email. info@fujita.co.jp