Development of a Roundness Measurement System for Small Diameter Shield Tunneling Machines

Downsizing of the roundness measurement system for Large Diameter Shield Tunneling Machines enhances construction quality of shield tunneling for small diameter

Fujita Corporation, a Daiwa House Group company (Headquarter: Shibuya-ku, Tokyo, President: Yoji Okumura) developed an improved "Roundness Measurement System for Mid-to-Large Diameter Shield Tunneling Machine in 2013. We have now developed a similar system for Small Diameter Shield Tunneling Machines and validated it through use in the construction of the Matsudo Line (Ichikawa City, Chiba Prefecture).

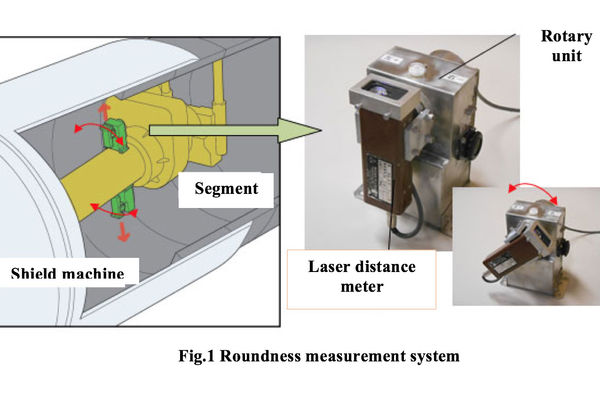

This newly developed measurement system consists of rotating laser distance meters attached at two diagonal positions and the control device within a shield machine. It measures the roundness of segments immediately after the assembly of segments in conjunction with shield excavation. This enables us to modify the abnormal displacement of the segments in early stage. As a result, a high quality primary lining can be constructed by giving feedback for shield machine control and adjusting the segment assembly process.

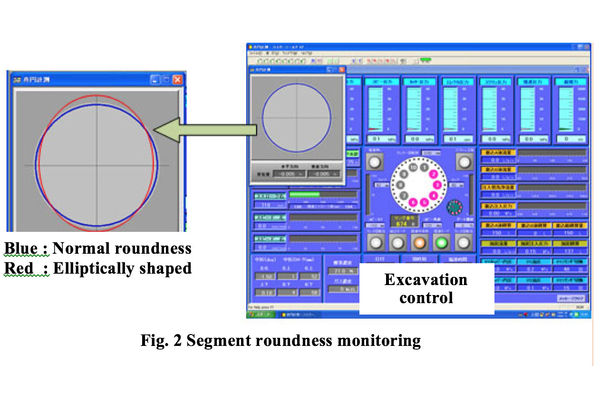

Segments are assembled and added cylindrically in shield construction to create tunnels. However, these segments are not always assembled in concentric circular forms within the shield interior; they can become decentered or elliptical. Especially when constructing sharp bends, the roundness of the assembled segments can be poor or distorted, and the joints between segments may have apertures and/or irregularities *1, that could result in concentrated mass on single segment while excavating. This could in turn lead to damage (chipping and splitting) and leakage. Therefore, focusing on keeping segments' roundness is crucial for construction of a high quality primary lining. However, because the measuring works must be done in the narrow space of a small diameter shield machine, it is extremely difficult to maintain the roundness precision. In addition, continuous roundness measurements immediately after assembling segments is delayed because the screw conveyor installed within the machine is in the way, and it is difficult to maintain precision when carrying out these measurements in a tight space. With our new system, a rotary laser measuring device is utilized in order to make it applicable for small diameter shield tunneling construction. We are aiming to spread the use of the newly developed system, increase the application examples, and examine further downsizing of the system.

Characteristics of the Roundness Measurement System for Small Diameter Shield Tunneling Machine

1) Capable of high-precision segment inner space measurement

A rotary laser measuring device has a measuring precision of ±1.5mm.

2) It measures simultaneously with shield excavation

The measurements are carried out in conjunction with the shield excavation, which enables quick analysis of the segment roundness that can be used in the next segment assembly process (refer to the diagram No. 2).

3) Downsizing measurement system

The control device and measuring device are separated in order to downsize them, which enables them to be retrofitted to small diameter shield machines.

[Matsudo Line Construction Site-Overview]

Construction Name: Construction of Edogawa River Left Bank Basin Waste Water Pipe and Drain (Matsudo Line 501-2 sector)

Construction Site: Ichikawa-city, Chiba prefecture

Client: Chiba Prefecture

Constructor: Specific construction joint venture with Fujita Corporation and

Hori Corporation

Construction Outline: Mud pressure shield, segment outer diameter: 2,000 mm, excavation length: 965m

*1 apertures and/or irregularities:

the misalignment or gap at the segment joints caused by poor segment assembly precision and outer load

---

ENDS

---

Fujita Corporation

Public Relations Office

Tel. +81-3-3402-1911

Fax. +81-3-3404-8477

Email. info@fujita.co.jp